NX for Manufacturing

Drive efficient end-to-end part manufacturing operations and deliver high-precision parts through digitalization.

Program CNC machine tools, control robotic cells, drive 3D printers and monitor quality using one software system. Digitally transform your part manufacturing business to gain productivity and increase profitability.

NX provides complete computer-aided manufacturing (CAM) software solutions for machine tool programming, post processing and machining simulation. NX CAM software’s advanced functions in each of its modules can maximize returns on your investments in the latest machine tool technology.

Adopted across many industries, NX CAM software delivers proven capabilities for manufacturing in the aerospace, automotive, medical device, mold and die, and machinery industries.

NX CAM provides a wide range of functionality, from simple NC programming to multi-axis machining, enabling NC programmers to address many tasks using one system. The flexibility of NX CAM means that the most demanding jobs can be completed easily. NX CAM software provides a wide range of functionality, from simple NC programming to high-speed and Multi -axis machining, enabling you to address many tasks with one system. The flexibility of NX CAM software means that you can easily complete the most demanding jobs.

Product Features

Attributes that Help You Grow Right

Reduced Production Cost

Less Production Time

Increased Product Quality

Modules

Domains Where Our Expertise Lies

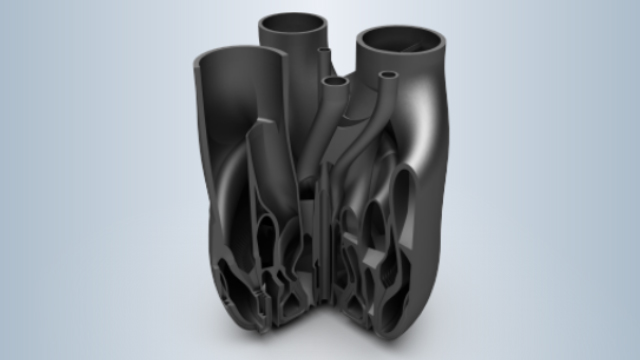

Additive Manufacturing

The most powerful, flexible, and innovative product development solution in the industry, NX for Design has the features, performance, and capabilities to help you get product to market faster than ever before.

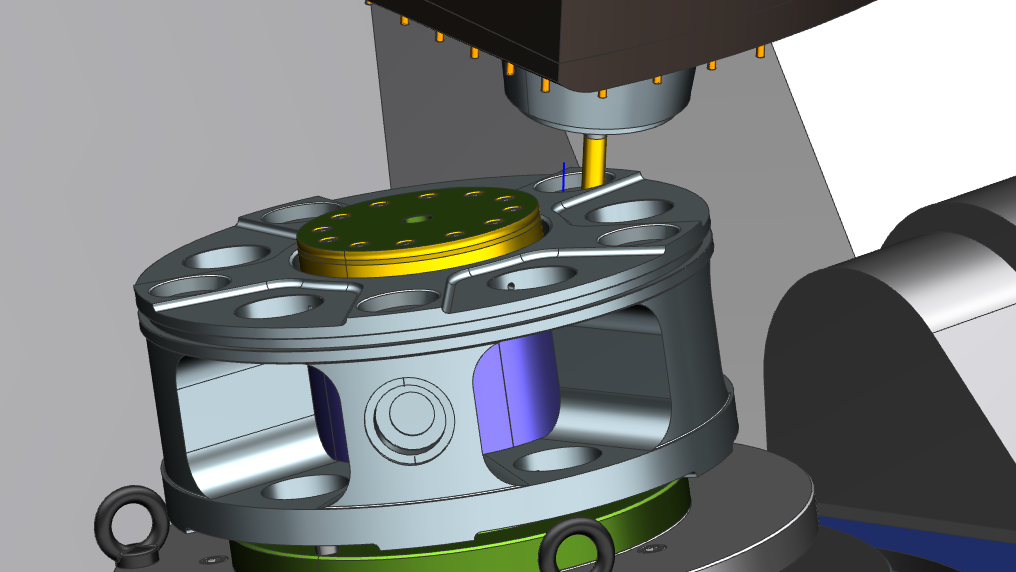

CAM Software

Automate NC programming and reduce cycle time with next-generation CAM software. Make better parts using advanced capabilities, such as intelligent high-speed cutting and automated feature-based machining.

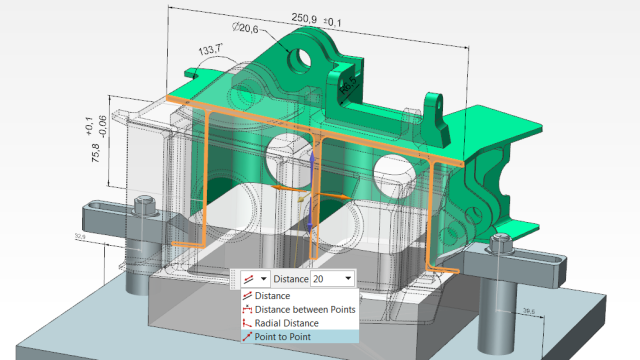

Design Tools for Part Manufacturers

NX provides powerful integrated Computer-Aided Design (CAD) that enables seamless manufacturing – from digital part models to finished products.

Part Quality Control

Validate quality using a digitalized process. The closed-loop solution seamlessly connects CMM inspection programming, execution, and measured data analysis to meet demanding requirements for product quality.

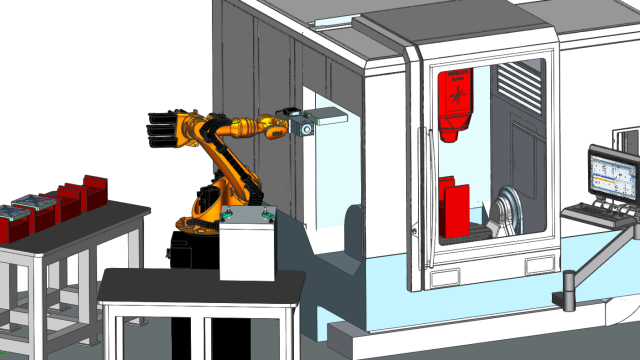

Robotic Automation

Modernize machining operations with robotics. Program and simulate robots to perform precise CNC machining and pick-and-place operations to expand automation and improve productivity on the shop floor.

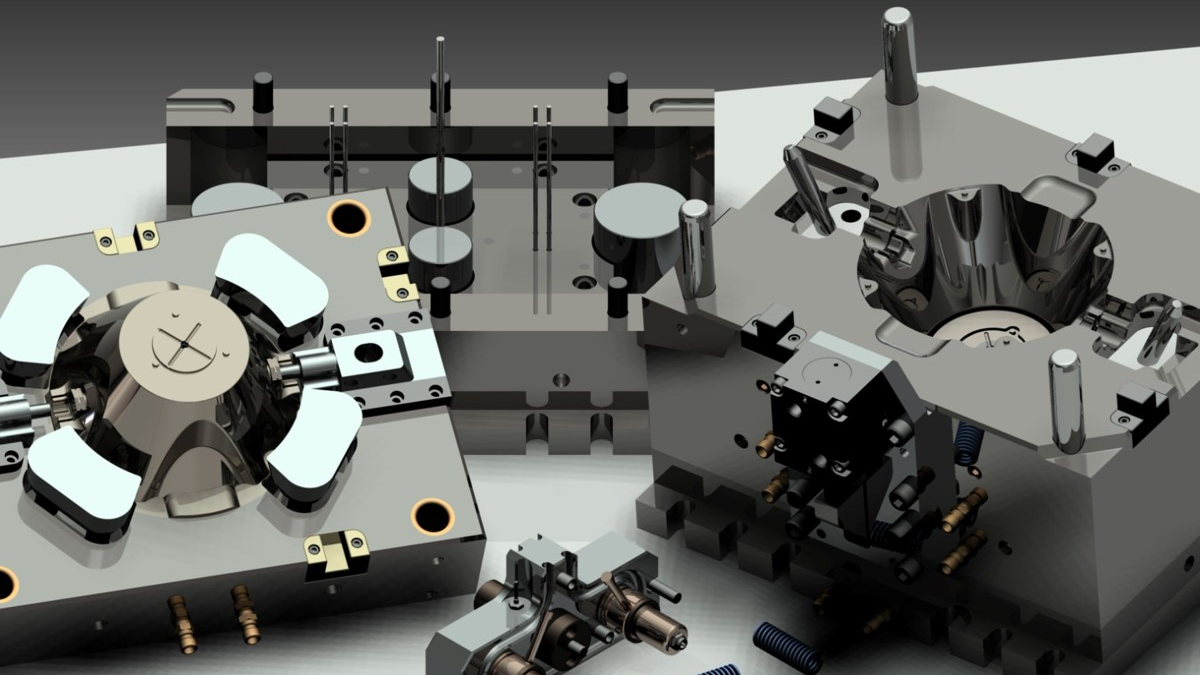

Tooling & Fixture Design

Automate the design of associative molds, fixtures, and progressive and stamping dies using process-based design applications.